From Paper to Platform: The Digital Leap

In the fast-paced world of manufacturing, agility and innovation are paramount. Bolzoni, a global leader in lift truck attachments and material-handling equipment, recognized the need to modernize its operations to stay ahead. Facing challenges like disparate processes across international plants and reliance on manual, paper-based systems, Bolzoni sought a solution that could unify and streamline its operations.

Enter Mendix—a low-code platform that empowered Bolzoni to digitize its processes rapidly and efficiently.

The Challenge: Diverse Systems and Manual Processes

With manufacturing plants spread across the US, China, Brazil, and Italy, Bolzoni grappled with:

- Inconsistent Processes: Each plant had its own set of procedures and technologies, leading to inefficiencies.

- Manual Quality Checks: Quality assurance relied on paper forms, which were prone to errors and delays.

- Integration Hurdles: Existing systems like SAP, Siemens Teamcenter, and Salesforce operated in silos, making data sharing cumbersome.

As Pietro Foroni, Quality & Engineering Technical Director at Bolzoni, aptly put it:

“We realized that the strategy is important. But what is really critical are two things: the people and the tool.”

The Solution: Embracing Mendix for Unified Innovation

In late 2022, Bolzoni adopted Mendix to bridge the gaps in its operations. The platform’s low-code nature allowed for rapid development and easy integration with existing systems.

Key Achievements:

- Rapid App Development:

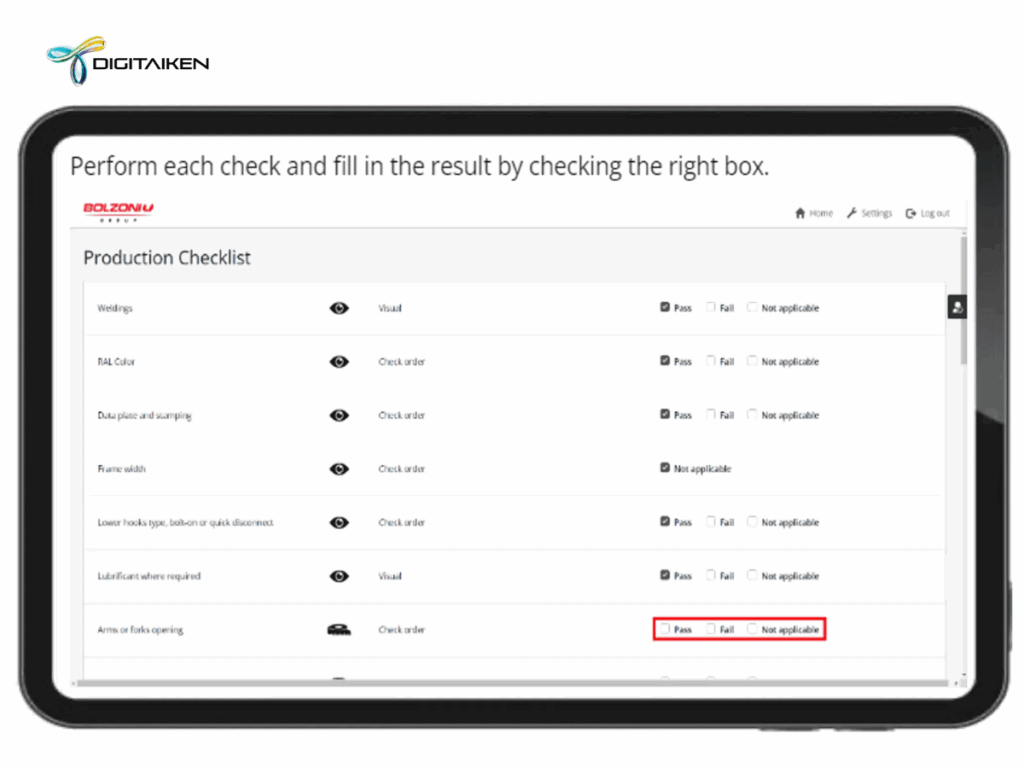

- Quality EndLine Checklist: Developed in just 2 weeks, this app digitized quality checks, integrating seamlessly with SAP Quality Management.

- Delivery Notes App: Rebuilt in 1 week, streamlining the delivery process and capturing digital signatures.

- Technical Documentation Portal: Delivered in 1 month, replacing a legacy system and integrating data from Teamcenter and SAP.

- Enhanced Integration:

- Mendix’s compatibility with SAP and Teamcenter facilitated smooth data flow between systems.

- Pre-built connectors and reusable UI components expedited development.

- Improved Data Transparency:

- Digital processes provided real-time insights, enabling proactive decision-making.

- Quality data became more accessible, allowing for trend analysis and continuous improvement.

Stefano Terzoni, IT Director at Bolzoni, highlighted the impact:

“For us, Mendix is completely the best solution for innovation.”

The Results: A Culture of Continuous Improvement

By leveraging Mendix, Bolzoni achieved:

- Employee Empowerment: Teams could adapt and iterate on applications, fostering a sense of ownership and innovation.

- Operational Efficiency: Reduced manual tasks and streamlined workflows.

- Faster Time-to-Market: Accelerated development cycles allowed for quicker implementation of solutions.

The success of this digital transformation has set the stage for future initiatives in customer support, logistics, and order management.

Looking Ahead: Building on a Strong Foundation

Bolzoni’s journey with Mendix exemplifies how low-code platforms can drive significant improvements in manufacturing. By focusing on people and leveraging the right tools, organizations can navigate the complexities of digital transformation with confidence.

As Terzoni aptly summarized:

“Our strategy is to collect and integrate information in these core systems. Mendix enables this in a way that it is now also becoming a core system for Bolzoni.”

Want to dive deeper into Bolzoni’s transformation journey?

Read the full case study on the Mendix website:

👉 Bolzoni Standardizes Manufacturing Processes and Accelerates Innovation

Ready to Transform Your Operations?

At DigiTaiken, we’re proud to partner with Mendix to deliver innovative solutions tailored to your business needs. Let’s explore how low-code can accelerate your digital transformation journey.

📩 Contact us today to learn more.